White Oak: Unveiling the Beauty Within

White Oak’s natural beauty is undeniable, but did you know the way it’s sliced can transform the entire look? Today, we’ll dive into the world of plain sawn, quarter sawn, and rift sawn White Oak. We’ll explore how each type is cut from the log, how it affects the grain pattern and stability, and which might be the perfect choice for your next project!

Slicing the Pie: Understanding the Cuts

Imagine a log as a round pie. Plain sawn lumber, also referred to as flat sawn, cuts slices parallel to the pie’s crust, yielding wider pieces than its rift and quartered counterparts.

In contrast, quarter sawing or rift sawing involves cutting the pie into quarters first, and then slicing those quarters. This method of sawing produces boards that are inherently narrower because they follow the pie’s radius, not its diameter.

The price of each of these cuts is directly related to the amount of waste involved in cutting them.

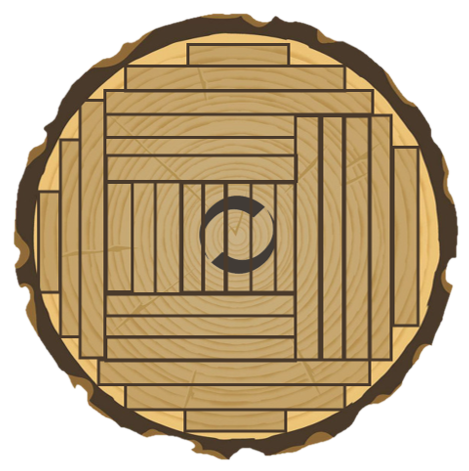

PLAIN SAWN: Anything but plain! Plain sawn boards are sliced straight through the log, revealing the familiar curved “cathedral” growth rings. The character makes plain sawn White Oak a perfect choice for those who love the inherent artistry of wood and want to incorporate its natural beauty into their space. This method of sawing provides the greatest yield from the log.

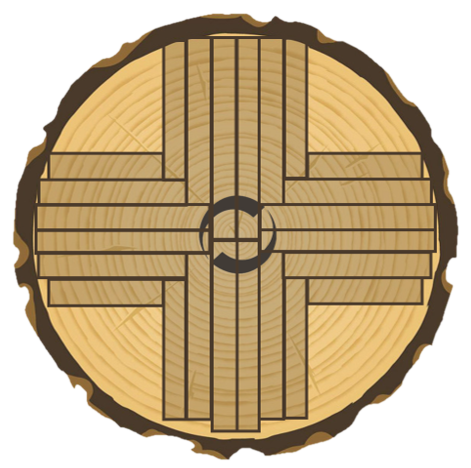

QUARTER SAWN: Quarter sawing prioritizes the visual appeal of the straight grain along with prominent medullary rays. When lumber is quarter sawn, these rays get sliced on an angle, creating a stunning visual effect known as “ray fleck” – a beautiful, wavy pattern within the wood. This method produces a more stable product, limiting movement across the width of the board and further enhancing stability. Note that quarter sawn can include 20% – 25% of rift sawn material, which is why you will often hear it referred to as “rift and quartered”.

RIFT SAWN: Similar to quarter sawn, but with an extra step! The quarters are sliced at an angle, resulting in a straight, linear grain throughout the board. Rift sawn offers the same dimensional stability as quarter sawn, making it perfect for hardwood flooring, high-end furniture and applications requiring increased dimensional stability. It is also the most costly and incredibly difficult to procure in widths or lengths that are conducive to architectural millwork. As with its quarter sawn counterpart, rift sawn can contain up to 25% quartered material.

Koetter Woodworking offers a wide selection of White Oak S4S in both plain sawn and quarter sawn. Additionally, we manufacture made-to-order products, including architectural moldings, doors, stair components, and more.

We hope that this has provided you with a better understanding of how White Oak’s transformation unfolds with each cut! When choosing White Oak for your next project, consider the balance between visual appeal, stability, and of course, your budget!